Cleaning And Sanitizing Program

Since cleaning and sanitizing may be the most important aspects of a sanitation program, sufficient time should be given to outline proper procedures and parameters. Detailed procedures must be developed for all food-product contact surfaces as well as for non-product surfaces such as non-product portions of equipment, overhead structures, shields, walls, ceilings, lighting devices, refrigeration units and heating, ventilation and air conditioning systems, and anything else which could impact food safety.

Cleaning frequency must be clearly defined for each process line . The type of cleaning required must also be identified.

The objective of cleaning and sanitizing food contact surfaces is to remove food that bacteria need to grow, and to kill those bacteria that are present. It is important that the clean, sanitized equipment and surfaces drain dry and are stored dry so as to prevent bacteria growth. Necessary equipment must also be clean and stored in a clean, sanitary manner.

Cleaning/sanitizing procedures must be evaluated for adequacy through evaluation and inspection procedures. Adherence to prescribed written procedures should be continuously monitored, and records maintained to evaluate long-term compliance.

The correct order of events for cleaning/sanitizing of food product contact surfaces is as follows:

Are Test Strips Required And Why

Commercial sanitizers and test strips are required by health department regulations, and in Colorado those are the Colorado Retail Food Establishment Rules and Regulations. Why do you need them? Because test strips tell you if the chemical sanitizing solution is the required concentration. Section 4-402 reads:

A test kit or other device that accurately measures the concentration in parts per million of the sanitizing solution shall be available and used.

How To Test Sanitizer Concentration

For a sanitizer, concentration is everything. If the concentration is too high, you could risk dangerous levels of chemicals left on food-contact surfaces, potentially causing chemical contamination.

Ensure your sanitizer has been mixed properly by using sanitizer test strips to check its concentration.

Also Check: Does Implant Birth Control Stop Your Period

How Do You Use Test Strips And How Often

Chlorine-based sanitizers: Dip the strip into the sanitizing solution, then immediately remove and compare to the color chart. If it reads between 50 ppm and 200 ppm, then the concentration is fine.

Quaternary ammonia sanitizers: Dip the strip into the sanitizing solution for 10 seconds, then remove and compare to the color chart. If it reads between 100 ppm and 400 ppm, then the concentration is fine.

Iodine-based sanitizers: Dip the strip into the sanitizing solution for 60 seconds, then remove and compare to the color chart. If it reads between 12.5 ppm and 25 ppm, then the concentration is fine.

If the concentration is either too low or too high, either add sanitizer or dilute as needed in order to achieve the required concentration.

How often do you need to check the concentration? The Colorado regulation does not specify. But you need to check often enough to ensure the proper concentration at all times. A minimum of twice a day is my recommendation.

If you have a high temperature dish machine in Colorado, you must provide a minimum temperature of 160 F on the surface of utensils/equipment to ensure that sanitizing has actually occurred. Since dish machine gauges can be inaccurate, purchase and regularly use hot water test labels.

Fryer oil and pH test strips are not required by the Colorado regulations.

What Is Sanitization And Why Is It Important

Good questions, and Im glad you asked! Here is the definition from Section 1-202:

Sanitization means the application of cumulative heat or chemicals on cleaned food-contact surfaces that, when evaluated for efficacy, is sufficient to yield a reduction 5 logs, which is equal to a 99.999% reduction, of representative disease microorganisms of public health importance.

Simply put, if you apply either sufficient heat, or sufficient chemical sanitizer, then nasty microbes that can make you sick are reduced by 99.999%. That protects you and your customers, and it is important. The regulations define how much is sufficient, and I discuss that next.

Recommended Reading: What Is The Best Time To Get Pregnant After Period

Cleaning Equipment In Place

You should clean your equipment in three instances: before using it, throughout the day as needed to prevent recontamination, and at least every 24 hours. Follow the proper process for cleaning in place.

For more information on how cleaning and sanitizing help keep you and your customers safe, get your food handlers card through our online training course.

Juli Shelley

Questions To Ask About All Hocl

Using the pros and cons list and answering the above questions can help you narrow in on which option to purchase but remember this important implementation tip: Start small with implementing any new product and dont make further changes until you have reason to believe that the product is a benefit to your organization. Changes, even great ones, take time.

CloroxPro and Clorox Healthcare are proud tooffer two RTU HOCl-based solutions for consideration in your organization. You can learn more about them here:

References:

Also Check: Will I Have A Period With An Iud

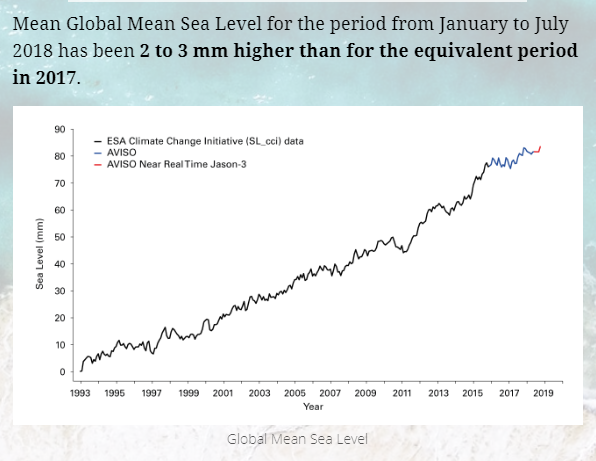

Water Chemistry And Quality

Water comprises approximately 95â99% of cleaning and sanitizing solutions. Water functions to do the following:

- carry the detergent or the sanitizer to the surface

- carry soils or contamination from the surface.

The impurities in water can drastically alter the effectiveness of a detergent or a sanitizer. Water hardness is the most important chemical property with a direct effect on cleaning and sanitizing efficiency.

Water pH ranges generally from pH 5 to 8.5. This range is of no serious consequence to most detergents and sanitizers. However, highly alkaline or highly acidic water may require additional buffering agents.

Water can also contain significant numbers of microorganisms. Water used for cleaning and sanitizing must be potable and pathogen-free. Treatments and sanitization of water may be required prior to use in cleaning regimes. Water impurities that affect cleaning functions are presented in Table 1.

What Is Food Grade Sanitizer

Food-grade, sometimes referred to as food-safe, sanitizers have been tested and certified safe for food contact. This means that even if the sanitizer comes into contact with food, it will not be harmful when ingested.

Sanitizers that have not been approved for food contact should not be used in food prep or food contact areas. Remember, these can be toxic if ingested.

Pro Tip:To determine if a sanitizer is safe for food contact surfaces, check the sanitizer label. If you are still not sure, reach out to the manufacturer or look for an EPA registration number.

Also Check: Negative Pregnancy Test But No Period

Presentation On Theme: Cleaning And Sanitizing Presentation Transcript:

1 Cleaning and SanitizingInstructor NotesOnce you have designed a sanitary facility, it is important to keep it that way. If you do not keep the facility and equipment clean and sanitary, food can easily become contaminated.It is important to use cleaning and sanitizing chemicals properly. If misused, they can be just as harmful as the illnesses they help prevent.

2 Apply Your Knowledge: Test Your Food Safety KnowledgeTrue or False: Chemicals can be stored in food preparation areas if they are properly labeledTrue or False: The temperature of the final sanitizing rinse in a high-temperature dishwashing machine should be 140°F True or False: Cleaning reduces the number of microorganisms on a surface to safe levelsTrue or False: Utensils cleaned and sanitized in a three-compartment sink should be dried with a clean towelTrue or False: Tableware and utensils that have been cleaned and sanitized should be stored at least 2 inches off of the floorInstructor NotesAnswers:False12-2

3 Cleaning Vs. SanitizingProcess of removing food and other types of soil from a surfaceSanitizingProcess of reducing the number of microorganisms on a clean surface to safe levelsSurfaces must first be cleaned and rinsed before being sanitizedInstructor NotesTo be effective, cleaning and sanitizing must be a two-step process. Surfaces must first be cleaned and rinsed before being sanitized.

Food Grade Sanitizer: What Are Approved Sanitizers For Food Service

Keeping any area clean and free of illness-causing germs and bacteria is important for businesses of all types, but it is especially critical in foodservice operations and other businesses that serve food.

Businesses serving food must lower the risk of cross-contamination and foodborne illness to keep guests protected from sickness.

Cleaning and sanitizing are essential to keeping your foodservice operation safe.

Soils, chemicals, germs and other contaminants left on surfaces increase the risk of infection, especially if food can potentially come into contact with these surfaces.

When food comes in contact with unclean surfaces, it risks picking up germs and transferring them to the person consuming the food.

With routine cleaning and sanitizing procedures, you can help maintain the safety of your foodservice operation and lower the risk of illness.

To clean and sanitize food contact surfaces, youll need a food grade, sometimes called food safe, sanitizer.

For the health and safety of your guests, you can not use a sanitizer unless it has been approved for food contact surfaces in these areas. Using a non-food grade sanitizer on a food contact surface could otherwise result in guest illness. In some cases, the sanitizer can even be poisonous if consumed.

Below, well review the difference between food grade sanitizers and non-food grade sanitizers. Well also cover the most common types of food-grade sanitizers as well as their advantages and disadvantages.

- E. coli

- Flu

Also Check: Missed My Period But Not Pregnant

Storing Chemicals And Sanitizers Properly

Labeling chemicals and sanitizers correctly is an important step in keeping food-contact surfaces safe. If a chemical is labeled incorrectly, or you are not sure what chemical it is, dispose of it.

Always store chemicals away from food and food-contact surfaces. Your chemical storage area should be separate from the food storage area to avoid contamination. If chemicals are stored close to food preparation areas, it is very easy for them to be spilled into food.

Finally, avoid using chemicals around where food is being prepared. Droplets of chemicals may become airborne and taint nearby food.

What Is The 3

In every foodservice operation spotless wares and clean utensils play an important role in customer satisfaction. Consumers associate spotty wares with dirt and carelessness, discouraging them from repeat visits.

Dirty tableware not only creates a negative perception of your facility but can put your patrons at risk. Lingering food particles and germs increase the risk of foodborne illnesses.

Ensuring your wares are clean will improve customer satisfaction and decrease the likelihood of foodborne illness, ultimately increasing your bottom line.

In the commercial warewashing environment, there are two ways to wash wares. Staff can manually wash wares using the 3-compartment sink method or automatically wash them with a commercial dishwasher.

Today, many operations prefer commercial dishwashers because of the enhanced productivity and effectiveness of the machine. Staff simply have to rinse the dishes and load the machine, allowing them to focus more on patrons. However, the FDA requires all commercial kitchens to provide a stainless steel sink with three compartments for the 3-sink method if there is not an appropriate automatic dishwasher available. Your local Department of Health may have additional requirements.

The 3-sink method is an older, more traditional way to wash dishes, but it is a reliable and effective dishwashing process.

Without the right procedures, the 3-sink method can lead to cross-contamination and spotty wares.

Read Also: How To Get Rid Of Teenage Period Cramps

The Truth About Hypochlorous Acid

With a long scientific history and many promising attributes, it is hard to understand why hypochlorous acid based disinfectants arent used in every commercial cleaning operation.1-3 In one recent review article focusing on the use as a disinfectant, the authors concluded that HOCl comprises many of the desired effects of the ideal disinfectant: It is easy to use, is inexpensive, has a good safety profile, and can be used to disinfect large areas quickly and with a broad range of bactericidal and virucidal effects.4,5 The reason is, as with most things, the devil is in the details. In this blog, Ill break down those details by answering these questions:

- What is HOCl?

- How are HOCl-based solutions made and sold?

- Which HOCl-based solution is right for you?

Washing Dishes In A Three

Three-compartment sinks make cleaning and sanitizing dishes easy and efficient. Here are the five steps for cleaning and sanitizing using a three-compartment sink:

Read Also: How To Talk About Periods With Your Daughter

Students Who Viewed This Also Studied

Lesson 1 Exam Medical Office Management II.docx

No School

Quiz – Chapter 12: 202120 Food Service Sanitation Mgmt FOS-2201-20326.pdf

Valencia Community College

Lesson 1 Exam Medical Office Management II.docx

Rockdale County High School CHEMISTRY ORGANIC CH

Phase Changes Gizmo Sheet.docx

Valencia Community College FOS 2201

Quiz – Chapter 12: 202120 Food Service Sanitation Mgmt FOS-2201-20326.pdf

How Are Hocl

There are three main ways that HOCl-based solutions are made and sold:

Don’t Miss: Proven Ways To Delay Your Period

What Is Hocl

HOCl is a weak acid that is formed when chlorine dissolves in water. It is used as an active ingredient in sanitizers and disinfectants because of its ability to break apart cell membranes, similar to the mechanism of action of sodium hypochlorite or hydrogen peroxide. Water solutions of HOCl are in the neutral to slightly acidic pH range. HOCl has many other common names including electrolyzed water, activated water, enhanced water, superoxidized water, and the most technically inaccurate of all is no-chemical .

HOCl is surprisingly effective at very low concentrations. It takes only a very small amount of HOCl to effectively kill bacteria and viruses and destroy proteins like inanimate pet allergens in comparison to higher pH bleach-based products. Despite this outstanding ability, it is also gentle on surfaces, and when no additional ingredients like surfactants or detergents are added to the final formula, HOCl solutions leave behind minimal residue. Evidence of this is demonstrated by the HOCl-based solutions on the market that are EPA approved as food contact sanitizers. These products do not require a rinse step when used on surfaces that come into contact with food.